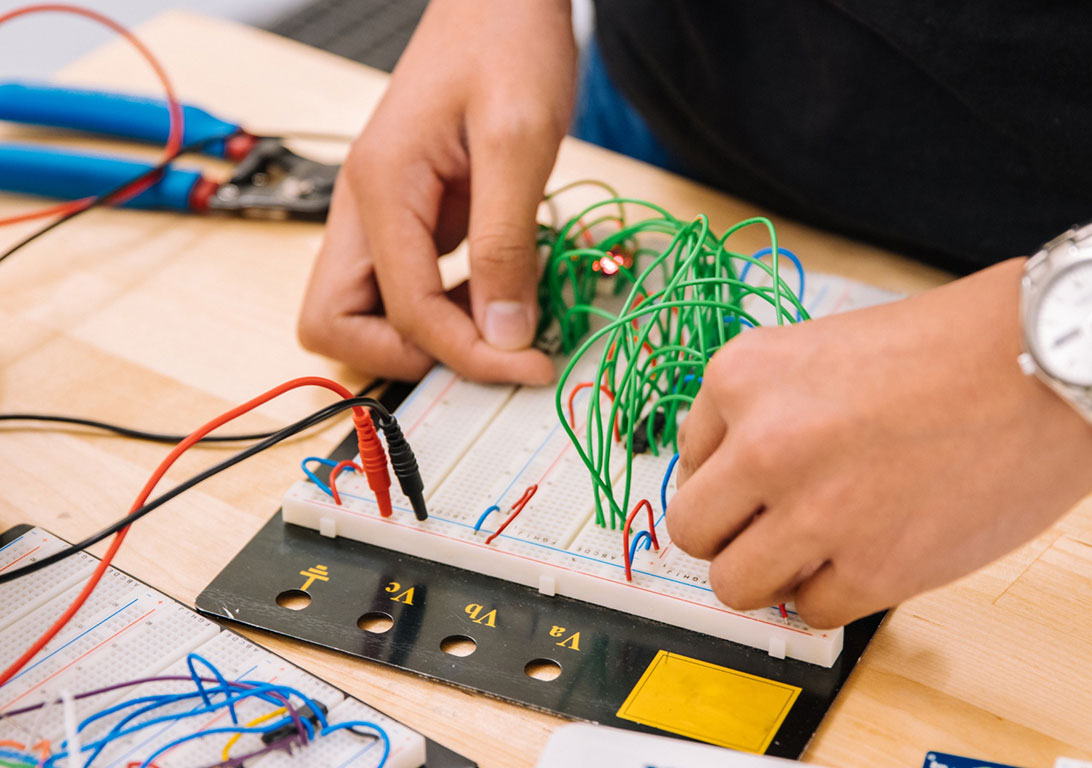

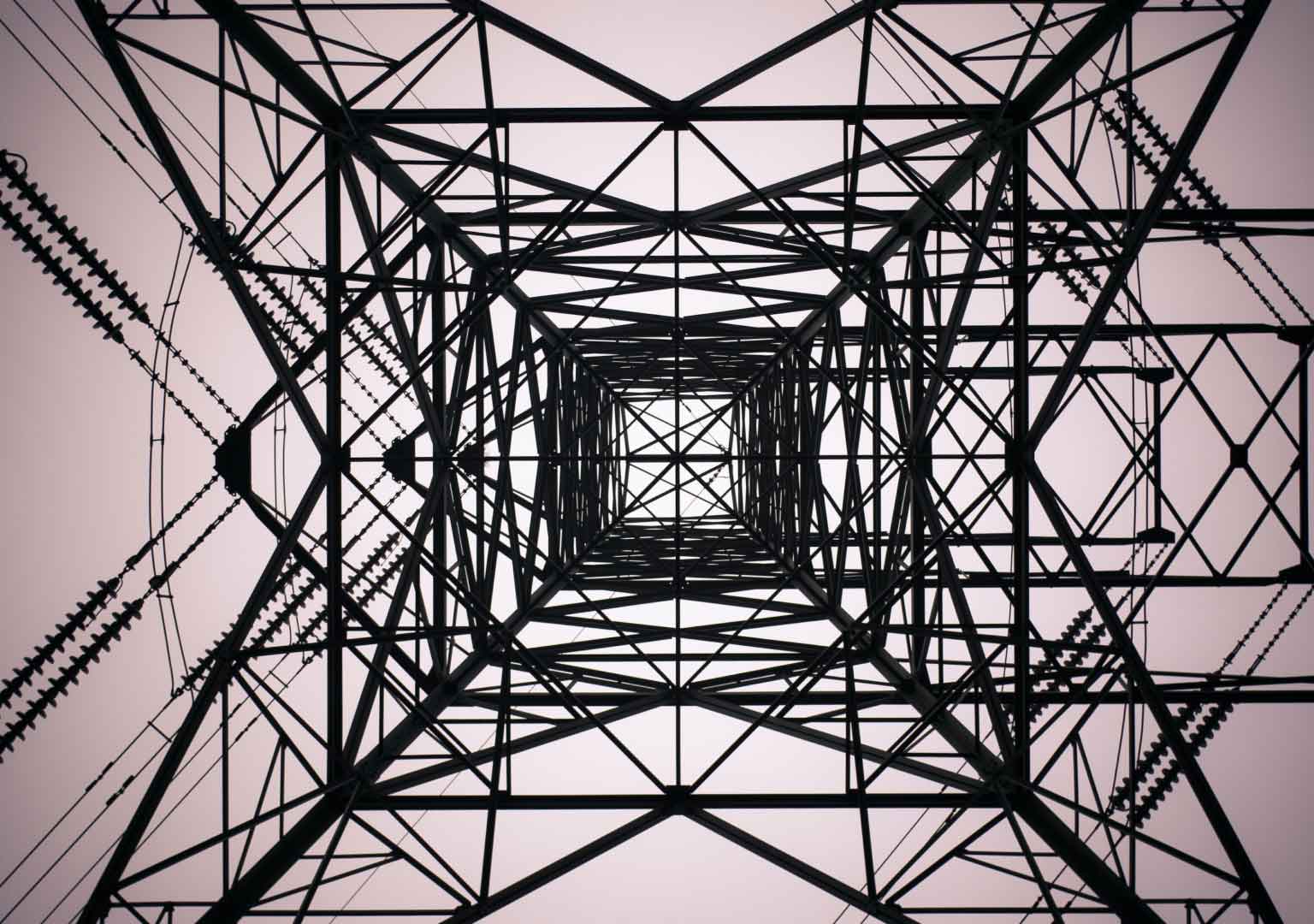

With the gradual expansion of the new energy vehicle market, the market demand for new energy batteries is also increasing. However, new energy batteries may generate safety hazards such as high temperatures and explosions during operation, so fire resistance testing must be conducted to ensure their safety. MOTIS provides excellent products and solutions for fire safety testing of new energy batteries.

With the popularization and promotion of solar photovoltaic technology, photovoltaic modules have also become a commonly used power generation equipment. However, during use, photovoltaic modules may face safety hazards such as fire. Therefore, conducting fire resistance testing of photovoltaic modules is very necessary. MOTIS provides excellent products and solutions for fire safety testing of photovoltaic modules.

The combustion performance of building materials refers to all physical and (or) chemical changes that occur when the materials burn or encounter fire. The combustion performance of building materials is measured by the flammability and flame propagation of the material surface, smoke, carbonization, weight loss and the generation of toxic biochemical substances under the action of open fire or high temperature. It is an important indicator to evaluate the fire performance of materials. Modis provides excellent products and solutions for fire safety testing of building materials.

The fire resistance test of rail transit can evaluate the thermal resistance, combustion performance, and flame retardancy of electronic components, ensuring that they can still operate normally under high temperature conditions and reducing fire risk. Motis will provide a reliable, efficient, and economical solution by conducting in-depth research on existing fire resistance testing technologies for rail transit, combined with the latest testing equipment and data analysis technology, to ensure the safe and stable operation of the rail transit system.

Motis provides a scientifically reliable solution for fire resistance testing of aviation materials. Through the latest testing equipment and data analysis technology, we can evaluate the combustion performance, thermal stability, and flame retardancy of materials to ensure that aviation materials remain stable and reliable in extreme environments, further improving flight safety.

We provide exceptional personalized support and a partnership that puts you first. We are ready with services, tools, and trained staff to work with you on your objectives:

With over 300 field service professionals in every major market, we are regionally close to you and ready to help.

Motis provides calibrations of the highest quality, offering a wide variety of factory and on-site calibration services. As a global provider, Motis has factory-trained engineers providing calibration services in Asia. All calibrations are traceable to the International System of Units through a local National Metrological Institute.

Additionally, our calibration laboratories are ISO/IEC 17025 accredited laboratories that have demonstrated the competence, impartiality, and performance capability required to provide our customers with a high level of confidence in the results from your materials testing system.

Accredited by the National Voluntary Laboratory Accreditation Program , Motis can provide factory and field calibration to our customers in almost every country of the world.

Preventive maintenance can help you maximize the use of the test system. Combining preventive maintenance with calibration services is the most convenient and economical way to meet the requirements of ISO 9001, ASTM E4 and ASTM E83 standards.

Motis engineers can access the required files, test site specific parts, and tools to maintain optimal performance of your equipment. Each on-site service includes a set of preset maintenance actions aimed at minimizing downtime, maximizing performance, and extending the service life of the testing system. To discuss how to protect your Modis products, please contact Modis' professional service personnel immediately.

Modis' technical support engineers can solve any thorny issues you may encounter during testing on a global scale. Technical support contract holders will receive priority responses to ensure that their questions receive the fastest response. For your convenience, we provide technical support through telephone, email, or remote online diagnostic assistant tools.

Our training curriculum includes a variety of courses that can meet the training needs of system operators and testing method developers, whether they are novice or expert users. The lecturer we hire will help you learn the best practical methods and teach you how to safely use your system and fully realize its potential. For your convenience, we can provide training courses at the Modis Training Center, regional sites around the world, our online learning network, or your own facilities.

Motis Remote Technical Support is provided by Motis Connect, which is the main service platform providing users with faster and simpler technical support. By using secure screen sharing and integrated augmented reality (AR) tools, operators can observe and support engineers' troubleshooting in a timely manner. Based on cloud technology, Motis support can easily locate your device records, evaluate problems, and provide solutions with unprecedented speed and efficiency.

No matter where you are in the world, our well-trained on-site service engineers can always come to your site for repairs. To minimize costs and downtime, these services can be purchased as part of standard or enhanced service agreements, or as needed.

We can also repair and refurbish your system in our global factories. Our dedicated engineers and technicians have years of experience in your company's equipment and can provide refurbishment services for various products, from sensors to actuators.

For ultimate protection, most systems currently in production can purchase extended warranties.

With the emergence of new technologies, your testing instruments can be improved to keep up with the growing demands of experimentation and industry. Modis' clearly defined product lifecycle stages can help you evaluate the system's supportability status and recommend the most effective and economical direction forward.

Regardless of the stage status of your system in our product lifecycle, if the system operates normally, Modis can calibrate it. However, if your goal is to unleash the full potential of your experimental investment, our product lifecycle is designed to help you make the right decisions, from software updates and upgrades to system upgrades, until complete system replacements.

We stake our reputation on the integrity of data. From the measurement of primary test data to result generation, we design and manufacture the full data integrity chain (e.g. load cells, sensor conditioning, and software). Additionally, we calibrate more than 90,000 of these sensors annually with the lowest accumulated uncertainty.

From protecting your brand to ensuring the safety of operators in your laboratory, MOTIS systems are designed to minimize risks inherent in mechanical testing.

With the largest team of service engineers in the industry, we’re here to ensure the long-term health of your system. We offer accessories and system upgrades to enhance your instrument as needs change over time. You can be certain your investment will last: in fact, the average age of MOTIS systems we maintain and calibrate is 18 years.

We service and calibrate more than 1,000 MOTIS systems in active use worldwide every year.

By 2022, Motis has independently developed more than 70 products.

Since 2010, Motis has applied for more than 96 patents.

SALES:(86) 0512-50358488

SERVICES:(86) 189 1573 7368

For service related questions, please fill out the contact form.